The Valuable Minerals in Heavy Mineral Sands – Ilmenite

Ilmenite (FeTiO3, Mn or Mg may substitute for Fe) is the main mineral mined for titanium. In its purer form it contains 55-65% titanium dioxide. It is often lower grade than this, due to impurities.

Impurities in ilmenite occur in two forms; grains, such as monazite, within the mineral lattice; and minerals, such as various silicates, physically attached to the ilmenite. The former can only be removed chemically, the latter can be physically removed, such as by grinding.

In 2016 The world produced 5.9Mt of ilmenite, the largest producers were South Africa, China and Australia. According to the United States Geological Survey, world reserves are 770Mt, enough for more than 100 years of consumption at current rates. But much of this is not necessarily economic at current prices.

Most ilmenite is recovered from heavy mineral sand deposits, formed where the source rocks are eroded and then deposited as sand on beaches. The heavy minerals are concentrated by wave and wind action. It is also mined from hard rock sources such as titano-magnetite deposits.

Virtually all ilmenite is used in the production of titanium dioxide, which is used in paint, plastics and paper manufacture. The remainder is used in welding-rod coatings, carbides, chemical and as a feedstock for titanium metal production. It is also used as a food colouring and in sunscreen.

Ilmenite is typically used as a feedstock for the sulphate pigment process, which subjects the ilmenite to sulphuric acid digestion and reduction. This process can accept lower grade titanium minerals than the alternative chloride process.

Prior to sale, ilmenite can be upgraded to “synthetic rutile” using the Becher process. This process roasts and then acid leaches the ilmenite to remove iron. It can also be upgraded to titanium slag and pig iron in an electric furnace, with a reductant such as anthracite.

Low grade ilmenite is not suitable for either process as any contaminants, such as silica, stay with the titanium dioxide.

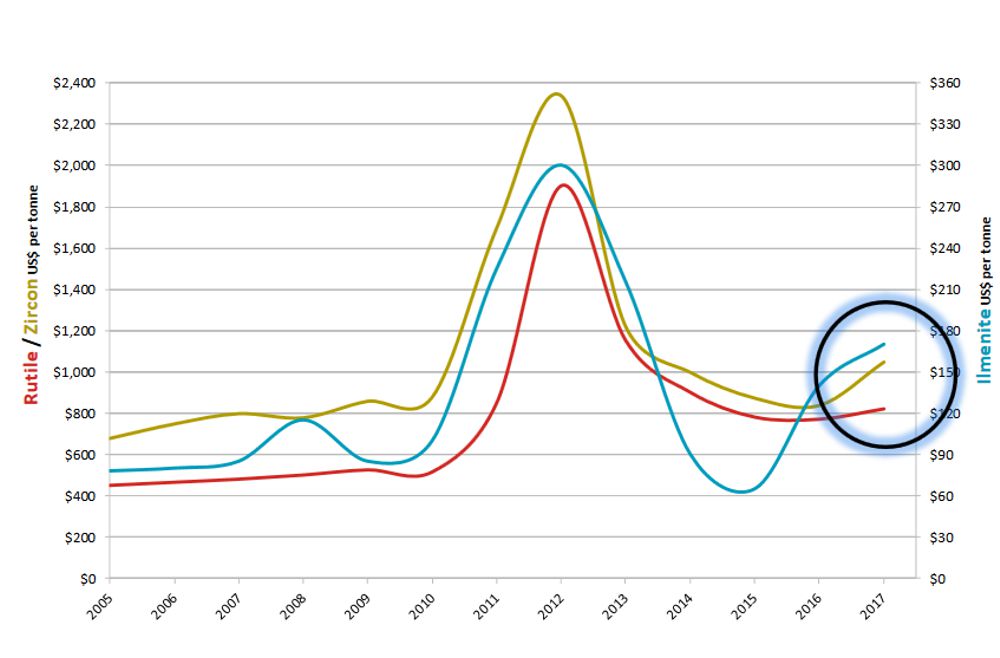

The price of ilmenite has been on a rollercoaster ride over the past few years. From high profitability in 2012 to loss making for many companies in 2015. The consensus is for the price to remain robust, although some are calling a top in 2018. The chart below shows that all three of the main HMS minerals have followed the same trend.

Chart Courtesy Base Resources Limited

Price volatility is an issue that has plagued the industry for years. This had led to many investors avoiding the sector. But things may be about to change. Going forward, trash minerals in HMS are increasing and grades are declining, leading to higher operating costs. Thus, any significant fall in price will quickly reduce supply.