Some Cement Facts and an Amazing Chart

Concrete and steel, along with abundant cheap energy, are the bedrock of industrial society. The most important raw materials for concrete and steel are cement and iron ore.

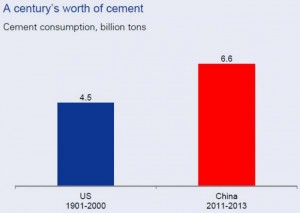

The chart below shows all you need to know about Chinese industrial growth. The world had never seen such rapid industrialisation as the US during the 20th century. And yet China has exceeded 100 years of US cement production in little more than a couple of years.

Data compiled by historian Vaclav Smil

Data compiled by historian Vaclav Smil

The manufacture of cement is a two stage process:

- Raw materials such as limestone, clay, silica sand and iron ore ( there are many others, depending upon the cement type) are crushed and heated to around 1,4500C. The resultant chemical reactions, which are poorly understood, result in the formation of “clinker”.

- The clinker is mixed with limestone and gypsum and is then very finely ground and prepared for transport.

Cement is primarily used in concrete. Concrete is comprised of cement, gravel, sand, water and air. Concrete has relatively low tensile strength and low ductility. This means it will crack or break very easily. This weakness is resolved by reinforcing the concrete, usually with steel reinforcing bars (“rebar”). Thus, virtually all concrete includes steel – the twin pillars of an industrial economy. Read more about steel here.

Conclusion

The chart above is just extraordinary. It certainly suggests that, even with its huge population, Chinese cement production will inevitably slow, reflective of a slowing economy. President Xi’s government is, of course, well aware of the balancing act required to avoid a hard economic landing. Let’s hope he succeeds, for all our sakes.